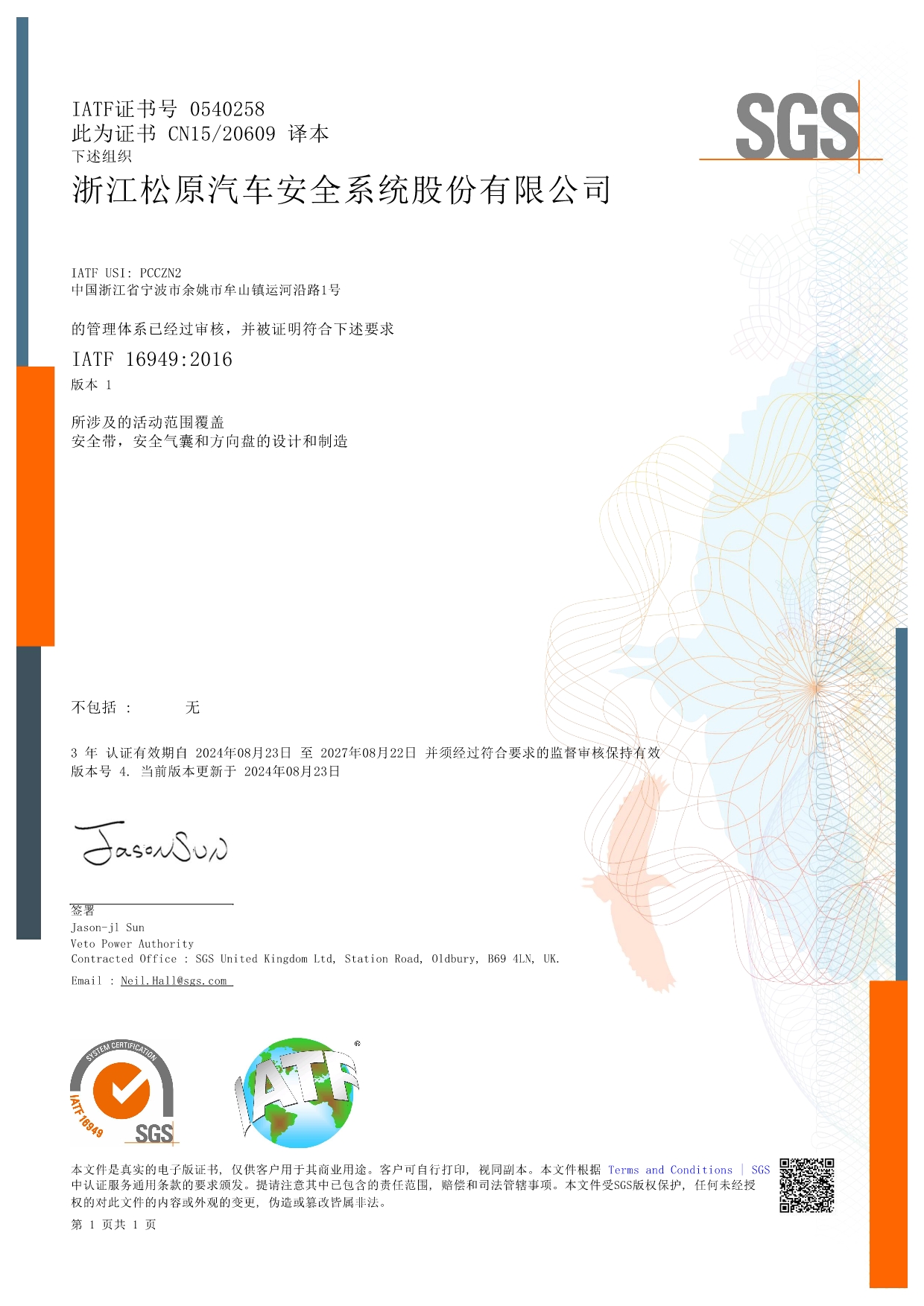

About Songyuan

Technology & Manufacturing

Safety Solutions

Integrated Capabilities

Markets & Services

Sustainability

Press Releases

Investor Relations

Contact Us